Download Mitsubishi Carbide

AXD Series

This homepage offers Mitsubishi Materials cutting tools information. General Catalog / Korean. General Catalog / Castellano.

| For steels |

| For stainless steels |

| For cast iron |

| For non-ferrous metal |

| For difficult to cut material |

| For hardened material |

| For finish cutting |

| For medium cutting |

| For rough cutting |

For Machining of Aluminium and Titanium Alloys

Multi functional milling cutter for high speed & performance machining of aluminum and titanium alloys*.

*For titanium alloys is only AXD4000.

Multi Functional Milling

AXD Series for excellent multi-functional performance.

Designed for high speed, efficiency and safety

At high spindle speeds the double clamping screws prevent insert displacement caused by centrifugal force. The double clamping offers both reliability and safety.

High Spindle Speeds Possible

Safe and reliable high spindle speed milling can be achieved due to the use of the double screw clamping and Mitsubishi Material’s proprietary “Anti Fly Insert” mechanism (Double AFI).

Mitsubishi Carbide Usa

To prevent vibration under high spindle speeds the holder is balanced to G6.3 or better at 10000min-1, according to the ISO1940 standard. (The holder is balanced without the inserts and the screws in place)

How do you download music in kia niro. Use of USB devices for purposes other than playing music files is prohibited. Image display and video playback are not supported. Use of USB accessories, including charge and heat though the USB I/F, can lead to reduced product performance or malfunctions.

Al-Ti-Cr-N accumulated coating series-MP9120

DLC coated LC15TF

DLC coating prevents the chips from welding on the insert rake face providing improved surface finishes and high-efficiency machining.

LC15TF can be used for both wet and dry machining.

TF15

Micro-grain cemented carbide with superior resistance to wear and fracturing. TF15 ensures stable cutting and efficient machining of aluminium alloy. The special mirror treatment on the rake face prevents chip welding for reliability and longer tool life.

It is necessary to choose the best insert according to the cutting conditions. Please select an insert from the tables below.

1st recommendation for stable cutting condition is the GL breaker with a strong cutting edge.

Selection of insert according to the feed per tooth and the required cutting depth

Selection of insert according to the width of cut and the required cutting depth

1st recommendation for machining aluminium alloys is GL breaker.

Under high-load conditions such as deep or high feed cutting, it is advisable to use the GM breaker.

Selection of insert according to wear resistance

Excellent Wall Accuracy

Mitsubishi Carbide Usa Website

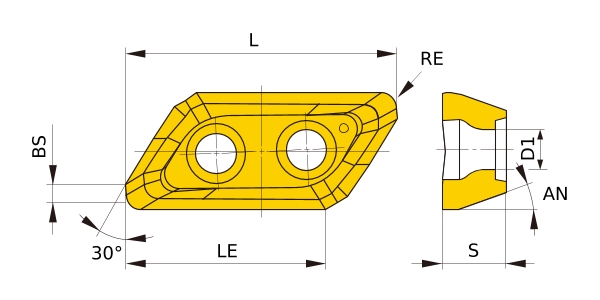

Specially designed G-class inserts with a helical cutting edge for excellent wall accuracy.

Low Resistance Inserts

An optimised helical flank and flank angle offers cutting edge strength and provides a large rake angle to reduce cutting resistance. Additionally a convex cutting edge is incorporated to ensure effective chip flow.

Comparison of surface finishes

Improved surface finishes by reducing feed mark

Mitsubishi Carbide Distributors

Cutting performance on Ti-6AL-4V

Stable tool life under high-load conditions

Cutting of aluminium alloy cast iron : Si content 9%

2.3 times longer tool life due to tougher cutting edge & PVD coating